Peddinghaus 510-DGA Miter Band Saw: A Comprehensive Guide

Accessing prints and manuals for your Peddinghaus machines, including the 510-DGA, is crucial for optimal performance and safe operation. Digital PDF versions are readily available.

Locating the correct manual ensures proper setup, operation, and maintenance of the 510-DGA miter band saw, maximizing its cutting capabilities.

The Peddinghaus 510-DGA miter band saw represents a robust solution for precise metal cutting in fabrication and welding environments. Understanding its capabilities begins with readily accessible resources, notably the official PDF manual. This document is paramount for unlocking the saw’s full potential.

As a miter cutting band saw, the 510-DGA excels at producing accurate angled cuts – specifically 45° and 60° in both directions. It’s designed to handle a variety of materials, from beams to tubes and hollow sections, making it a versatile asset. Accessing the manual provides detailed insights into material handling, including utilizing features like the PeddiRotator.

The manual isn’t merely a guide; it’s a key component of safe and efficient operation. It details the saw’s technical specifications, cutting capacities, and operational procedures, ensuring users can confidently integrate it into their production workflows. Proper utilization, guided by the PDF, maximizes productivity.

Key Features and Specifications

The Peddinghaus 510-DGA boasts a double miter design, a core feature enabling precise 45° and 60° cuts, both left and right. The PDF manual details these capabilities, emphasizing superior saw clamping for optimal accuracy. Cutting capacity is substantial, handling beams up to 2 to 27.6 inches, alongside tubes and hollow sections.

Key specifications, thoroughly outlined in the manual, include its robust construction and focus on integrating seamlessly into production lines – it’s more than just a cutting device. The manual also clarifies material handling procedures, including optional accessories like the PeddiRotator.

Understanding these features, as detailed in the PDF, is vital. The 510-DGA isn’t simply a band saw; it’s a precision tool designed for efficient fabrication and welding applications, and the manual unlocks its full potential.

Understanding the Manual & Documentation

Accessing the Peddinghaus 510-DGA PDF manual is essential for safe and efficient operation, detailing procedures and specifications for optimal performance.

Accessing the Peddinghaus 510-DGA PDF Manual

Locating the Peddinghaus 510-DGA PDF manual is a straightforward process, typically initiated through the official Peddinghaus website or by contacting their customer support directly. Online resources often provide direct links to downloadable manuals, ensuring users have immediate access to critical information.

These digital manuals encompass comprehensive details regarding machine operation, maintenance schedules, troubleshooting guides, and safety precautions. Utilizing the PDF format allows for easy storage, searching, and printing, facilitating convenient access whenever needed. Furthermore, accessing the manual digitally ensures you always have the most up-to-date version, reflecting any revisions or updates made by Peddinghaus.

Properly utilizing the manual is paramount for maximizing the lifespan and performance of your 510-DGA miter band saw.

Importance of the Manual for Operation & Maintenance

The Peddinghaus 510-DGA PDF manual is absolutely vital for both safe and efficient operation, as well as consistent, reliable maintenance. It details proper setup procedures, ensuring accurate cuts and minimizing the risk of operational errors. Understanding the manual’s guidance on material handling is also crucial for preventing damage to both the machine and the workpiece.

Regarding maintenance, the manual outlines a routine schedule, specifying necessary inspections, lubrication points, and component replacements. Adhering to this schedule prevents costly downtime and extends the saw’s operational life. Furthermore, the manual provides troubleshooting steps for common issues, empowering users to resolve minor problems independently, reducing reliance on external service.

Ignoring the manual can lead to improper use and void warranties.

Operational Procedures

Referencing the Peddinghaus 510-DGA PDF manual is essential before operation; it details setup, cutting parameters, and angle adjustments for optimal results.

Setting Up the 510-DGA for Cutting

Prior to initiating any cuts, thoroughly consult the Peddinghaus 510-DGA PDF manual for detailed setup instructions. Ensure the machine is positioned on a level surface and properly grounded for safety. Verify all guards are in place and functioning correctly, as outlined in the documentation.

Carefully inspect the blade for any signs of damage or wear, referencing the manual for blade selection guidelines. Adjust the blade tension according to the material being cut, following the specified parameters. Securely clamp the material using the saw’s clamping system, ensuring it’s aligned correctly for the desired cut. Double-check all adjustments before powering on the machine, always prioritizing safety as detailed within the manual.

Performing Miter Cuts (45° & 60°)

The Peddinghaus 510-DGA excels at precise miter cuts, offering both 45° and 60° capabilities in both left and right orientations. Refer to the PDF manual for detailed instructions on adjusting the miter scale and locking mechanisms. Ensure the material is securely clamped before engaging the cutting process.

The manual emphasizes the importance of verifying the miter angle with a protractor for accuracy. Slowly lower the blade into the material, maintaining consistent pressure. After the cut, carefully inspect the angle to confirm it matches the desired specification. The manual provides troubleshooting tips for achieving clean, accurate miter cuts, maximizing the saw’s versatility.

Adjusting Cutting Parameters for Different Materials

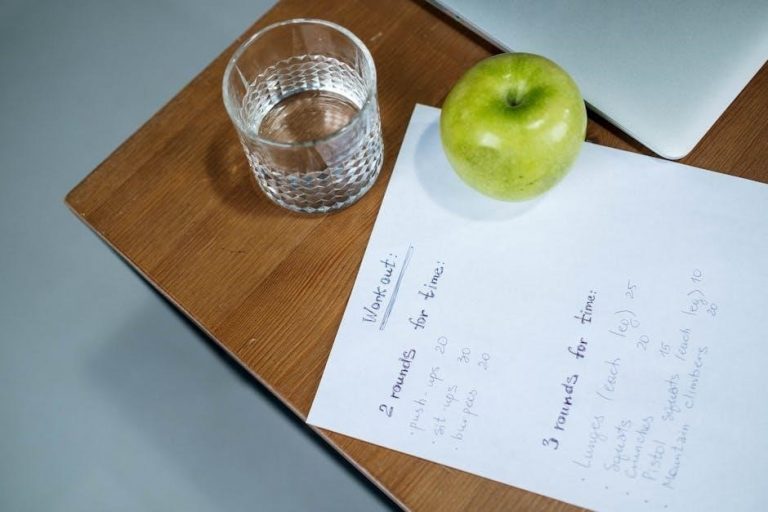

The Peddinghaus 510-DGA’s PDF manual details crucial adjustments for various materials. Blade speed and feed rate are primary parameters; harder materials require slower speeds and feed rates. The manual provides a chart outlining recommended settings for steel, aluminum, and other common fabrication materials.

Proper blade tension is also critical, detailed within the manual, ensuring clean cuts and preventing blade breakage. Adjust the guide blocks to closely support the blade, minimizing deflection. The manual stresses the importance of testing cuts on scrap material before processing valuable stock, optimizing parameters for each specific application and material type.

Safety Precautions

The Peddinghaus 510-DGA PDF manual emphasizes strict adherence to safety guidelines. Always review emergency stop procedures and general band saw operation protocols before use.

General Safety Guidelines for Band Saw Operation

Prior to operating any band saw, including the Peddinghaus 510-DGA, a thorough understanding of general safety protocols is paramount. The manual stresses the importance of wearing appropriate personal protective equipment (PPE), such as safety glasses and hearing protection, at all times.

Ensure the work area is clean, well-lit, and free of obstructions. Never operate the saw if fatigued or under the influence of substances. Familiarize yourself with the location and operation of the emergency stop button – a critical safety feature detailed in the PDF manual.

Always maintain a firm grip on the material being cut and never reach over or across a moving blade. Proper material support is essential to prevent binding and kickback. Regular inspection of the blade and saw components, as outlined in the manual, is vital for safe operation.

Specific Safety Considerations for the 510-DGA

The Peddinghaus 510-DGA, with its double miter design for 45° and 60° cuts, requires specific safety attention. The manual emphasizes secure clamping of material, given the angled cutting capabilities, to prevent movement during operation. Always verify the saw clamp is functioning correctly.

Due to the saw’s capacity for handling beams, tubes, and hollow sections, proper material support is crucial to avoid blade binding. The PDF manual details recommended support methods for various material types and sizes. Be mindful of the blade’s path and potential for material kickback.

Regularly inspect the miter angle locking mechanisms to ensure they are securely fastened before initiating a cut. Never attempt to adjust the miter angle while the blade is running. Adherence to these guidelines, detailed in the manual, ensures safe operation.

Emergency Stop Procedures

The Peddinghaus 510-DGA’s PDF manual clearly outlines critical emergency stop procedures. Immediately pressing the large, red emergency stop button halts all saw functions, crucial in unforeseen circumstances. Familiarize yourself with its location before operating the machine.

Following activation, the manual instructs users to disconnect the power supply to prevent accidental restarts during inspection or maintenance. Do not attempt to reset the saw until the cause of the emergency is identified and rectified.

The manual also emphasizes the importance of a clear evacuation path and designated personnel trained in emergency response. Regular drills, referencing the manual’s guidance, are recommended to ensure swift and effective action in critical situations, prioritizing operator safety.

Maintenance and Troubleshooting

The Peddinghaus 510-DGA PDF manual details routine maintenance schedules and common issue resolutions. It provides blade replacement guidance and troubleshooting steps for optimal performance.

Routine Maintenance Schedule

The Peddinghaus 510-DGA PDF manual outlines a comprehensive routine maintenance schedule vital for longevity and precision. Daily checks should include inspecting the blade for wear and proper tension, alongside verifying coolant levels.

Weekly tasks involve cleaning the saw frame and table, lubricating moving parts as detailed in the manual, and examining the blade guide system for alignment. Monthly procedures necessitate a thorough inspection of electrical connections and a check of the miter angle accuracy.

Furthermore, the manual recommends semi-annual inspections of the blade drive system and a complete coolant flush. Adhering to this schedule, as documented in the 510-DGA’s PDF manual, minimizes downtime and ensures consistent cutting quality.

Common Issues and Troubleshooting Steps

The Peddinghaus 510-DGA PDF manual details common issues and troubleshooting steps to minimize downtime. Blade drift can often be corrected by adjusting blade tension or guide bearings, as illustrated in the manual.

If encountering inaccurate cuts, verify miter angle settings and ensure the saw clamp is securely fastened. Electrical issues should be addressed by a qualified technician, referencing the wiring diagrams within the manual.

The manual also provides guidance on resolving coolant system problems and diagnosing motor overheating. Regularly consulting the 510-DGA’s PDF manual empowers operators to efficiently address minor issues and maintain optimal performance.

Blade Replacement Procedures

The Peddinghaus 510-DGA PDF manual provides detailed blade replacement procedures, emphasizing safety precautions. Begin by disconnecting power and relieving blade tension, as outlined in the manual’s instructions.

Carefully remove the blade guard and follow the diagram to detach the old blade, noting its orientation for correct installation. When installing the new blade, ensure proper tooth direction and secure tensioning, referencing the manual’s torque specifications.

Reinstall the blade guard and verify its functionality before restoring power. The 510-DGA’s PDF manual stresses the importance of using the correct blade type and regularly inspecting blade condition.

Technical Details & Capabilities

The Peddinghaus 510-DGA PDF manual details miter cutting ranges, beam/tube capacity, and material handling features. It showcases superior clamping and cutting precision.

Miter Cutting Capabilities & Range

The Peddinghaus 510-DGA excels in miter cutting, utilizing a double miter design as detailed in its PDF manual. This allows for precise angled cuts, accommodating both 45° and 60° angles, crucial for fabrication and welding projects.

The manual emphasizes the saw’s ability to handle cuts in both right and left orientations, increasing versatility. Understanding these capabilities, as outlined in the documentation, is vital for maximizing production workflow efficiency. The 510-DGA’s design ensures superior clamping during miter cuts, contributing to accuracy and clean finishes.

Referencing the manual provides specific details on achieving optimal miter cuts for various materials and dimensions, ensuring consistent and reliable results.

Material Handling with the 510-DGA

The Peddinghaus 510-DGA’s PDF manual details effective material handling techniques for optimal performance. The saw is designed to process beam, tube, and hollow sections, with specific guidance provided within the documentation.

Accessories like the PeddiRotator, referenced in available resources, enhance material handling capabilities, allowing for efficient positioning and secure clamping. Proper material support is crucial, and the manual outlines best practices to ensure safe and accurate cutting.

Understanding the saw’s limitations regarding material size and weight, as specified in the manual, is essential for preventing damage and maintaining operational safety. Careful attention to these guidelines maximizes productivity.

Cutting Capacity (Beam, Tube, Hollow Sections)

The Peddinghaus 510-DGA PDF manual provides precise cutting capacity specifications for various material types. It details the maximum dimensions for beam, tube, and hollow sections the saw can effectively process.

According to available information, the 510-DGA can handle beams up to 2 to 27.6 inches. The manual will specify exact limitations based on material grade and cutting angle. Understanding these limits is vital for safe and accurate operation.

Referencing the manual ensures operators avoid overloading the saw, preventing potential damage and ensuring consistent cut quality. Detailed charts within the documentation illustrate capacity variations for different configurations.

Applications & Usage

The Peddinghaus 510-DGA manual details its integration into fabrication and welding workflows, showcasing its role as a precise cutting device for steel production.

Typical Applications in Fabrication & Welding

The Peddinghaus 510-DGA, as detailed within its manual, excels in diverse fabrication and welding applications. It’s frequently utilized for precise angle cuts on structural steel beams, tubes, and hollow sections, essential for building frameworks and supports.

The saw’s miter cutting capabilities, specifically 45° and 60° angles, are invaluable in creating complex joints and assemblies. Welders rely on the 510-DGA’s accuracy to prepare materials for clean, strong welds. The manual highlights its suitability for projects ranging from architectural metalwork to heavy industrial construction, ensuring efficient material processing and reduced waste.

Furthermore, the manual demonstrates how the machine streamlines production by providing consistent, repeatable cuts, accelerating project timelines and improving overall quality.

Integrating the 510-DGA into Production Workflows

The Peddinghaus 510-DGA’s manual emphasizes its role as more than just a cutting device; it’s a crucial step in a streamlined production process. Integrating the saw effectively requires understanding its capabilities and limitations, as outlined in the documentation.

By utilizing the 510-DGA, fabrication shops can minimize material handling and reduce the need for secondary operations. The manual details how to optimize cutting parameters for various materials, ensuring consistent results and minimizing blade wear. This leads to increased throughput and reduced costs.

Proper integration, guided by the manual, transforms the saw from a standalone tool into a vital component of a cohesive, efficient workflow.